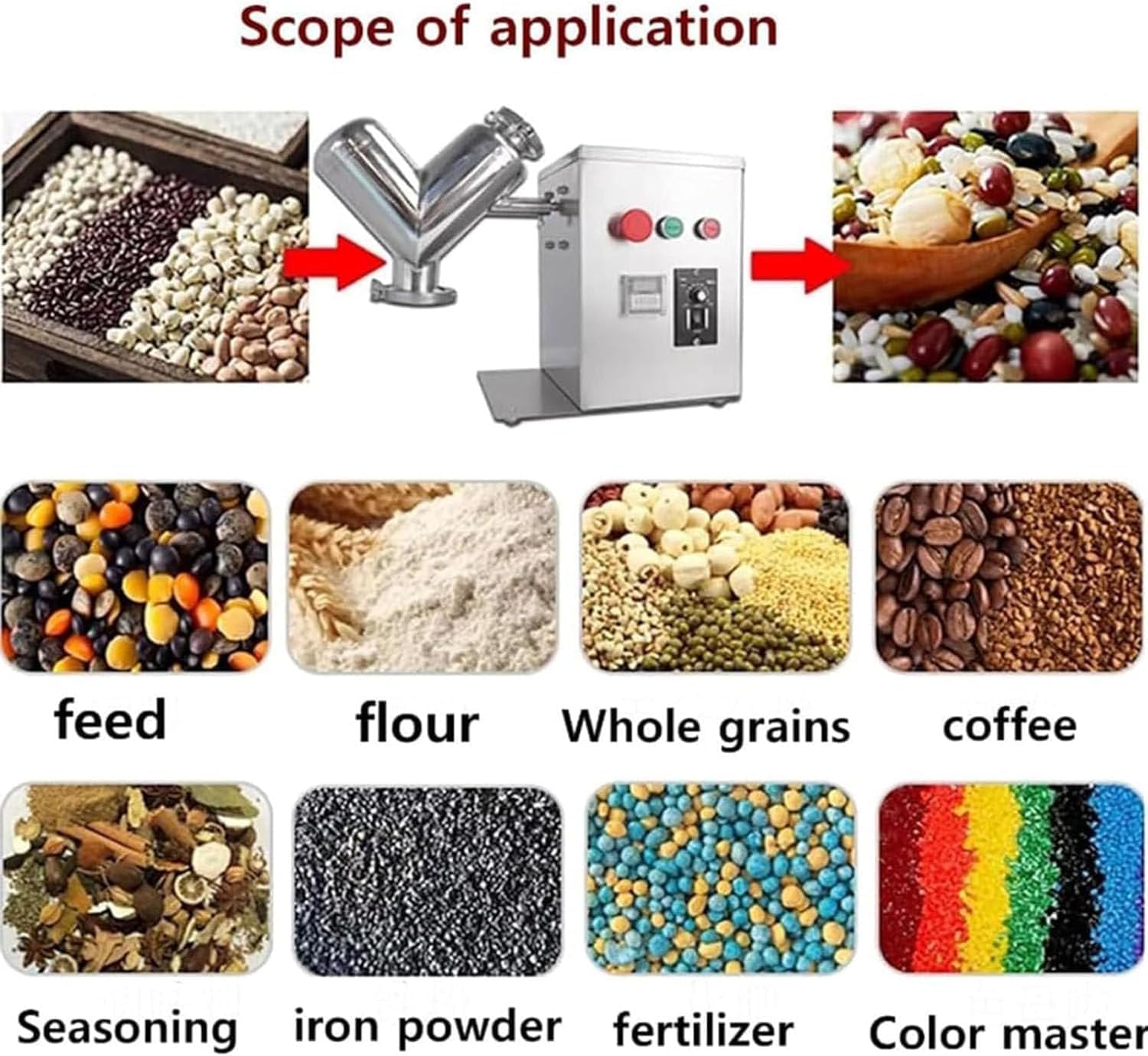

Small Mixer V-Type Experimental Mixer,2L Lab Shear V Type Dry Powder Mixer, Mixing Machine for Powder, 304 Stainless Steel Blender

The parts in contact with the raw mate

-

Detail

Product Description

Parameters:

Volume of the cylinder:2 L

Max. Work Capacity: 0.8 L

Best filling quantity: 0.56kg

Voltage:110V or 110V

Power: 0.55 KW

Mixing speed: 24 r/min

Overall Size: 450*280*500mm

Using Method:

1. Place the machine on a flat and sturdy surface so it will run smoothly and efficiently.

2. Check the gear reducer to ensure there has enough oil.

3. Run an empty load. Check carefully to make sure the machine is under good condition.

4. Roll the feeder station. Then, open the lid and feed the materials. The materials should not exceed 40% of the cylinder's limit.

5. Next close the feed lid and run the machine to working. You must stop it if there is any abnormality.

6. It is necessary to clean the hopper completely when changing materials or when finishing a run. -

Customer ReviewsNo comments